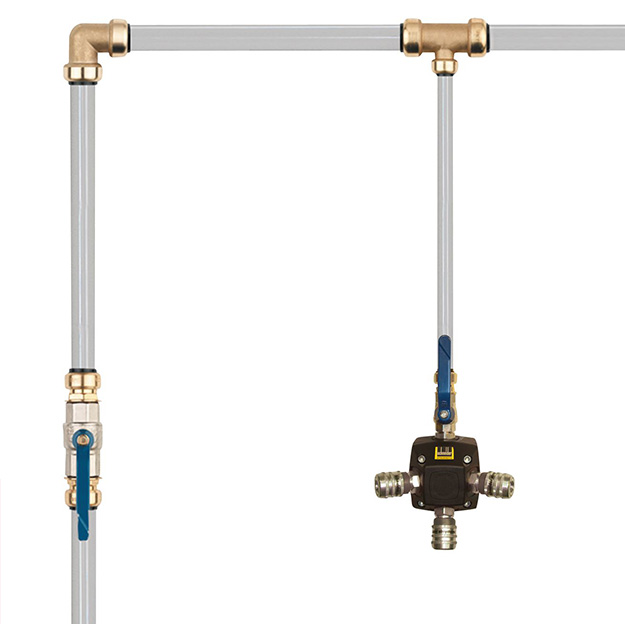

Distributing Compressed Air

Distributing compressed air – using our plug-in pipe systems reduces your energy consumption and economizes your operation costs.

Distributing compressed air using plastic (Polyamide PA 12W) and latest also aluminum piping can only support the quality of the distributed compressed air. Among their undisputed advantages we have to point out excellent lifetime, high flexibility and an easy and quick assembling. This kind of compressed air piping does not require any further paint treatment or anything similar.

The piping system is available also in stainless steel version.

Main advantages:

- assembling time savings up to 50%

- high chemical resistance (no rust)

- optimal compressed air flow conditions

- minimal lifetime 50 years

- low weight

- minimal pressure drop out

- materials used are environmentally friendly

Main Attributes of Schneider air piping and fitting systems:

- maximal reliability up to the pressure of 15 bar thanks to the metal fittings

- pipes are made of Polyamide (PA 12) or a special aluminum alloy

- Pipes and fittings made from stainless steel as well

- easy and quick assembling

- no soldering, no threading or sealing are necessary, the connection remains stable by itself

- after assembling, the compressed air piping system is ready for use

- saving costs, after disassembling all the system parts can be used and put back together again

- no chance of crack in the fitting metal body

- corrosion resistant fittings and their smooth inner walls offer full air flow and its optimal conditions

- fittings are not sensitive to some small fluctuation and mechanical load

- distributing compressed air using aluminum piping is visually esthetic (even if the pipes have to be hanged)